Products

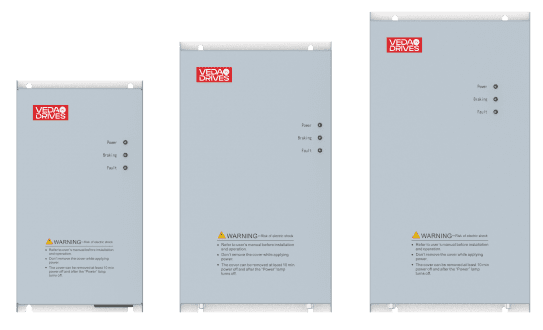

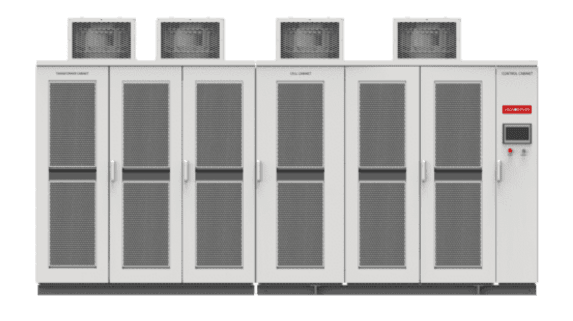

Medium-voltage soft-starters

VEDA-in MV SFT soft-starters are designed for the smooth starting and stopping of asynchronous motors with a squirrel-cage rotor and synchronous motors with a voltage of 1.2–10 kV.

Please contact us to request a calculation

check list for the order

- Specifications

- Review

- Advantages

• Rated voltage: 3 kV, 3.3 kV, 6 kV, 6.6 kV, 10 kV, 11 kV (+10 %, –15 %)

• Frequency: 45–65 Hz

• Control circuit power: 110–240 V AC (+10 %, –15 %)

• Motor current: 33–100 % of rated soft starter current

• Initial voltage: 10–50 % of rated voltage

• Current limiting: 100–400 % of motor current

• Acceleration time: 1–30 s

• Deceleration time: 1–30 s

• Alternative setting: Two sets of parameters for start/stop with separate settings: motor current, initial voltage, current limit, acceleration and braking time

• Auxiliary contact: 1 normally open/closed, 8 A, 250 V AC, 2000 VA

• End of acceleration: 1 normally open/closed, 8 A, 250 V AC, 2000 VA

• Fault contact: 1 normally open/closed, 8 A, 250 V AC, 2000 VA

• Communication interfaces: ModBus RTU, ProfiBus DP

• Operating temperature: –10…+50 °C

• Storage and transport temperature: –20…+70 °C

• Cooling system: Natural or forced air cooling

• Air humidity: No more than 95 %, without condensation

• Altitude: No more than 1000 m

• Environmental protection: IP31, IP42, IP54

Voltage regulation is carried out by controlled thyristors. VEDA-in MV soft starters cannot control asynchronous motors with a wound rotor. Structurally, VEDA-in MV SFT represents a basic cell soft starter cabinet in a basic configuration, as well as a system of additional cabinets for input and output cells and an optional controller cabinet.

Each MV soft-starter is calculated individually based on a completed questionnaire

• Reduction of voltage dips and blackouts.

• Elimination of mechanical impacts on equipment and reduction of wear.

• Reduction of starting current.

• Smooth starting and stopping of the motor.

• Easily adjustable and user-friendly interface.

• Fault log.

• Start statistics log.

• Low-voltage test mode for soft starters.

• Current limiting.

• No additional voltage required for high voltage synchronization.

• Prevents excess pressure in the system during pump start-up.

• Eliminates backflow valve shock during smooth pump stop.

• Selection of the optimal start curve depending on the load type.

• Alternative settings for start/stop characteristics for different load modes.