Products

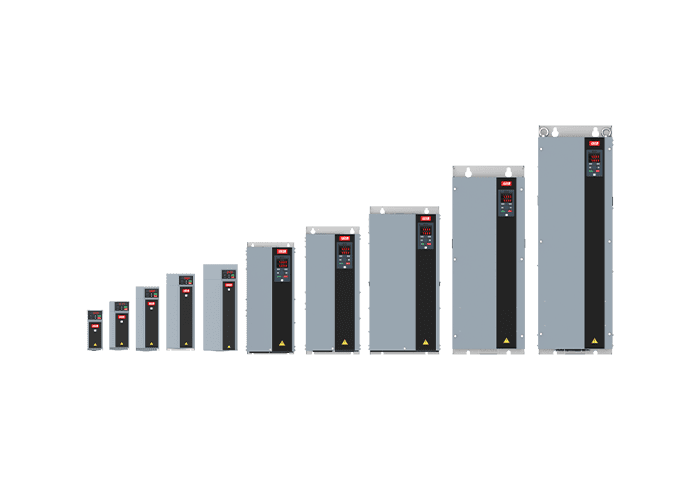

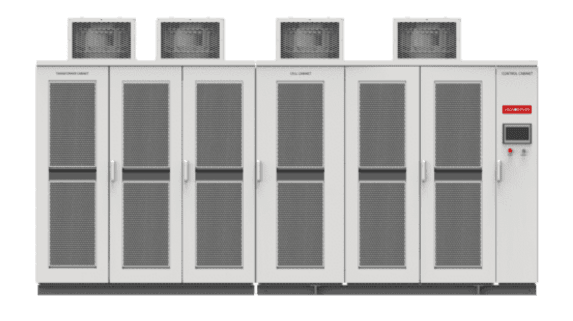

RD30 Crane DriveFor precise control and long life of the crane

The RD30 Crane Drive is designed for use in cranes and offers an easy and quick to install software description. Due to the automatic function "select the type of application", it is possible to put the equipment into operation with an optimal operating mode in the shortest possible time.

Please contact us to request a full price list

check list for the order

- Specifications

- Review

- Application

- Advantages

• Power range: 0,75 - 560kW

• Input voltage: T4: 3×380V (660V by request)

• Mains frequency: 50/60 Hz ±5%

• Output frequency: 0–299 Hz ± 0.5%

• Overload capacity: 150% for 1 minute, 180% for 10 s, 200% for 0.5 s

• Motor type: Asynchronous, synchronous

• Motor control type: U/f, vector control without/with feedback; separate voltage and frequency setting

• Switching frequency: 1–16 kHz

• Display: Built-in digital

• Case: IP20 (IP54 by request)

• Operating temperature: -10 °C ... 50 °C (+60 without load)

The RD30 Crane Drive has extensive functionality for efficient and reliable use in cranes. At the same time, the ease of installation makes it an attractive solution for modern crane systems.

Braking resistors are used to remove excess energy when the drive is operating in generator mode, especially when performing rapid braking operations. It is important to note that the RD30 frequency converters up to 55 kW have a built-in reinforced brake unit for connecting resistors. This ensures efficient and safe operation of the crane system when rapid and controlled braking is required.

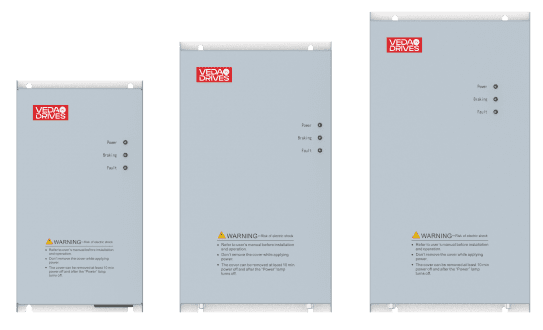

It is also possible to use the VEDA-in RD05 and VEDA-in RD11 series to drive the crane movement.

• Cranes

• Сrane movement

• Other lifting mechanisms

• An improved algorithm for controlling the mechanical brake.

• Keeping the load at zero speed at start and stop.

• Reverse without applying brakes.

• Reinforced brake transistors.

• Special start mode for lifting applications.

• The ability to use TTL and HTL encoders.

• Monitoring of PTC and PT100 motor thermistors.

• Signal processing of limit switches.

• Basic anti-corrosion 3C3 coating of boards.

• Support for various communication protocols: Modbus RTU (built-in), Modbus TCP/IP, CANopen, Profinet, Profibus.

-

€ 1 002.80

323х116х175 mm

€ 1 002.80

323х116х175 mm

11A00AAB007

RD30-T4-0025-CR-IP20-BU

Input 3x380V Output power 11kW Rated output current 25A Overload current, 150% 37.5A Brake unit built-in

-

€ 1 294.44

383х142х225 mm

€ 1 294.44

383х142х225 mm

11A00AAB008

RD30-T4-0032-CR-IP20-BU

Input 3x380V Output power 15kW Rated output current 32A Overload current, 150% 48A Brake unit built-in

-

€ 1 367.12

383х142х225 mm

€ 1 367.12

383х142х225 mm

11A00AAB009

RD30-T4-0038-CR-IP20-BU

Input 3x380V Output power 18kW Rated output current 38A Overload current, 150% 57A Brake unit built-in

-

€ 1 686.36

383х142х225 mm

€ 1 686.36

383х142х225 mm

11A00AAB010

RD30-T4-0045-CR-IP20-BU

Input 3x380V Output power 22kW Rated output current 45A Overload current, 150% 67.5A Brake unit built-in

-

€ 2 101.28

433.5х172х225 mm

€ 2 101.28

433.5х172х225 mm

11A00AAB011

RD30-T4-0060-CR-IP20-BU

Input 3x380V Output power 30kW Rated output current 60A Overload current, 150% 90A Brake unit external

-

€ 2 649.60

433.5х172х225 mm

€ 2 649.60

433.5х172х225 mm

11A00AAB012

RD30-T4-0075-CR-IP20-BU

Input 3x380V Output power 37kW Rated output current 75A Overload current, 150% 112.5A Brake unit external