Almaty’s district heating network supplies heat to a city of two million. To enhance efficiency and service quality, the company implemented a modernization program. One key project in the Southeast district boiler house involved frequency control-based smooth starting of network pumps in cascade sequence.

Heating source capacity: 136 MW (117 Gcal/h).

Heating system: open, two-pipe. Heat supply is centralized, serving heating, ventilation, and hot water with a temperature curve of 70-150 °C.

Boiler house equipment: steam and hot-water boilers, preheaters, network pumps at 720 m³/h each.

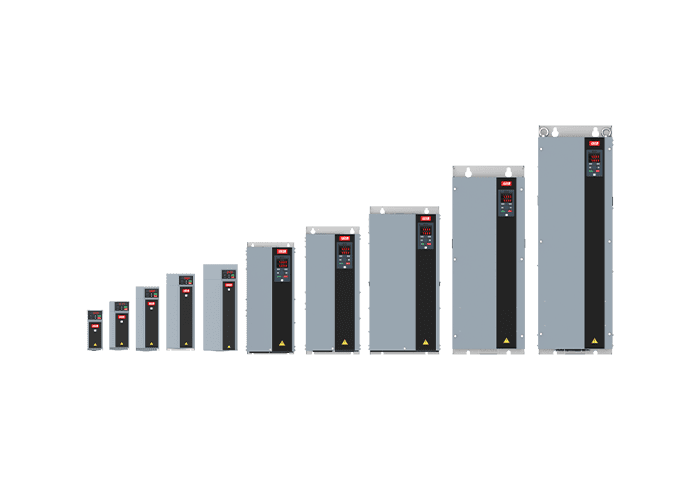

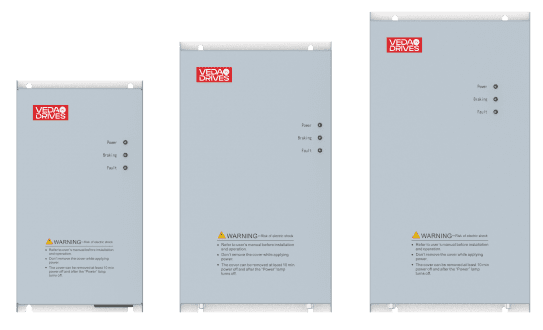

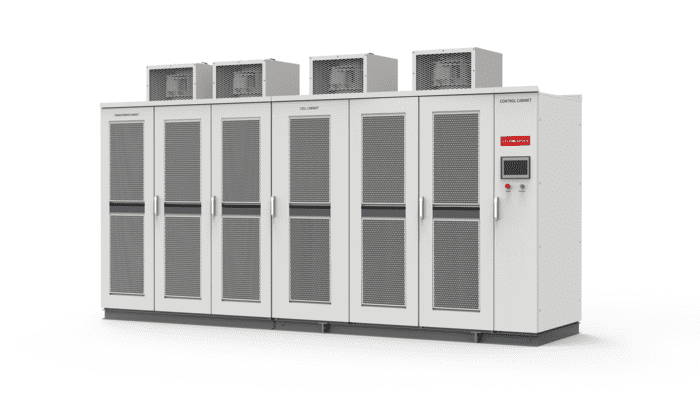

VEDA-IN DRIVE MVD Solution

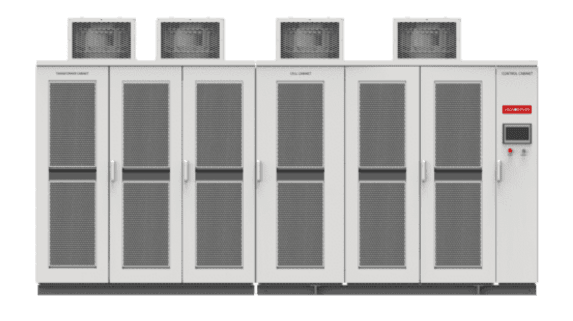

In 2020 Engineering company Silumin‑Vostok installed a 10 kV, 500 kW medium-voltage frequency converter, VEDA-IN DRIVE MVD, inside a modular block building to regulate the network pumps.

One VEDA-IN DRIVE MVD unit controls five motors in cascade.

When the first pump reaches maximum speed and VEDA-IN DRIVE MVD synchronizes with the grid frequency, it smoothly switches the pump from the converter to direct supply without hydraulic shock.

Then the next pump starts the same way. A reactor limits inrush currents.

This prevents hydraulic shocks and voltage dips during startup.

VEDA-IN DRIVE MVD also regulates pressure and flow in the network header via one pump’s performance.

Frequency control significantly boosts electric equipment lifespan, enhances energy efficiency, and reduces operating costs. One pump’s reduced energy use (avg 20 %) yields over 736 000 kWh annual savings.

Expert Comments

Evgeny Volkov, Head of Drive Equipment at Silumin‑Vostok, said the economic feasibility study favored high-voltage frequency converters over conventional soft starters. The solution enables system pressure maintenance by adjusting pump performance—leading to significant electricity savings. It’s simple and replicable at any pump station or boiler plant.

Silumin‑Vostok engineers optimized Drives equipment usage. VEDA-IN DRIVE MVD manages both asynchronous and synchronous MV motors, executing smooth starts and acceleration for any of the five network pumps. Upon reaching required parameters, the PID controller takes over performance regulation. The drive provides motor protection and diagnostics as standard.

VEDA-IN DRIVE MVD Advantages

Efficiency: 98.5 % (excluding transformer)

Stable operation even during voltage dips

More than 5 years of successful operation of the frequency converter

Copper transformer, compact size

Benefits

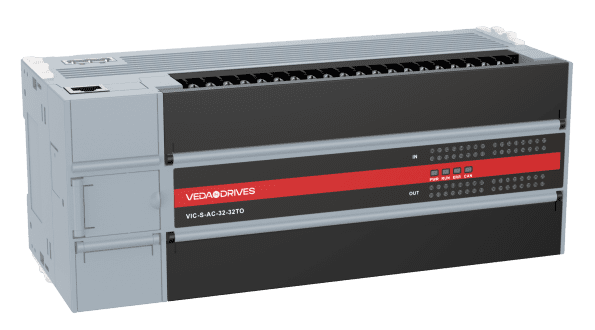

Using frequency control raises automation, improves process control without extra devices, and maintains parameters accurately. Multiple industrial communication protocols simplify integration with SCADA and DCS. Compared to throttling methods, it eliminates emergency shutdowns and maintenance downtime. Smooth starts extend motor lifespan by 10 %, and the absence of hydraulic shocks prolongs piping and fittings life by 1.5×.

About Silumin‑Vostok

Silumin‑Vostok LLP is Kazakhstan’s largest provider of comprehensive industrial automation and power solutions. As a VEDA-IN DRIVES distributor and service partner, they implement drive-based projects and support systems.